Keep up with the latest IoT-based building automation, and follow us on LinkedIn!

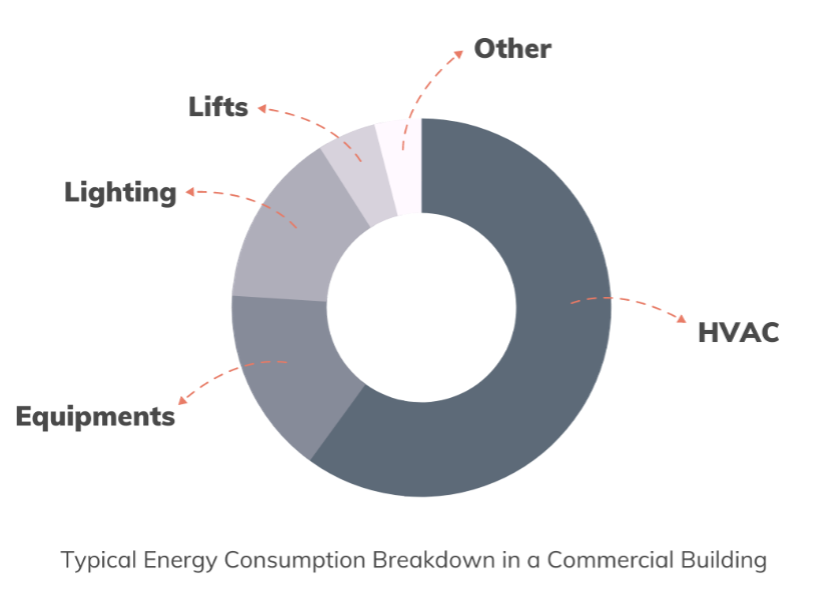

Commercial buildings account for 40% of the global energy consumption. 60-70% of this consumption goes towards the Heating Ventilation and Air Conditioning (HVAC) systems of the building. Inefficient operations can easily account for 20-30% of the total energy waste. Eliminating such a waste can help reduce global energy consumption by 10%. This is beneficial not only for businesses in terms of cost effectiveness, but also benefits the environment by lowering greenhouse gas emissions. It’s also our responsibility to plug such leakages in our attempt to pass on a planet that is better than the one we inherited from our previous generations.

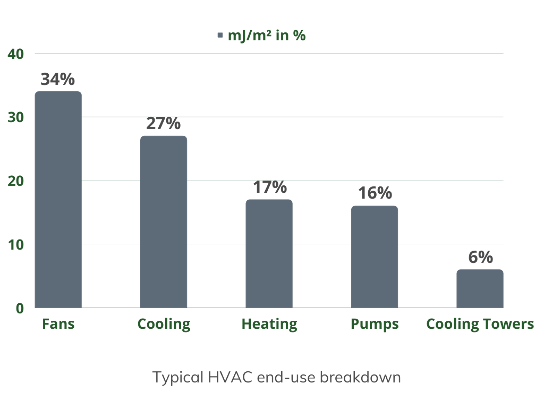

If we further break down the HVAC system by the energy consumed by its individual components, we can see that in a typical setting:

-

34% of the HVAC’s energy is used by the fans for air circulation and ventilation.

-

27% of the energy is used by chillers to produce chilled water for cooling.

-

17% is used by boilers to produce hot water for heating.

-

16% is used by pumps for the circulation of hot water, chilled water and condenser water.

-

6% is used by cooling towers for heat rejection.

HVAC systems are rightly considered as “energy guzzlers” for these obvious reasons. Hence optimizing them becomes a necessity. There have been several challenges with the traditional HVAC systems that limit their potential for the need-of-the-hour energy optimization.

Challenges in a traditional HVAC system

1. Lack of Visibility

In a traditional HVAC system, a lot of energy is wasted due to its operations even when it is not required e.g., during night times or over the weekends. This is usually due to lack of visibility into certain factors like operating hours, occupancy rates, temperature, humidity, and indoor air quality. This results in unnecessary HVAC run hours and hence energy wastage.

2. Lack of Smart Automation

Traditionally, HVAC systems are controlled manually which can lead to overcooling or undercooling as the reliance is on human intervention alone. There’s a lack of smart automation that can take into account certain key metrics necessary to maintain the right ambient environment like Ambient temperature, humidity & IAQ levels; Chiller return water temperature; occupancy rate, etc. and based on that automatically and smartly control the assets resulting in better occupant comfort in addition to energy savings.

3. Lack of Proper Maintenance

i) Wear & Tear of mechanical components

HVAC is a complex system that relies on a number of mechanical components such as belts, bearings etc. The system’s performance can be negatively affected by the wear & tear of such components that may result in undercooling, overcooling, heating issues, or airflow issues. Repairing these components after they’ve failed leads to disruption in HVAC’s operation leading to occupant discomfort. Moreover, often these repairs cost much more than if their regular maintenance is undertaken following a proactive maintenance approach.

ii) Dirty condenser or evaporator coils

Dirty evaporator coil can degrade the efficiency of both the furnace and the air conditioner and make the system work harder. Dirt and debris can clog the evaporator coils of the system, significantly reduce the efficiency and wear it out much sooner. Furthermore, indoor evaporator coil can become dirty, especially if the furnace filters are not changed frequently.

IoT powered HVAC system

What is IoT?

The Internet of Things or IoT refers to a system of interrelated and internet-connected devices that are able to collect and transfer data and/or perform control actions over a network without human intervention. A complete IoT system usually has five aspects – sensors/actuators, connectivity, data processing, user interface and closed-loop actuation/ticketing.

How IoT works in an HVAC system?

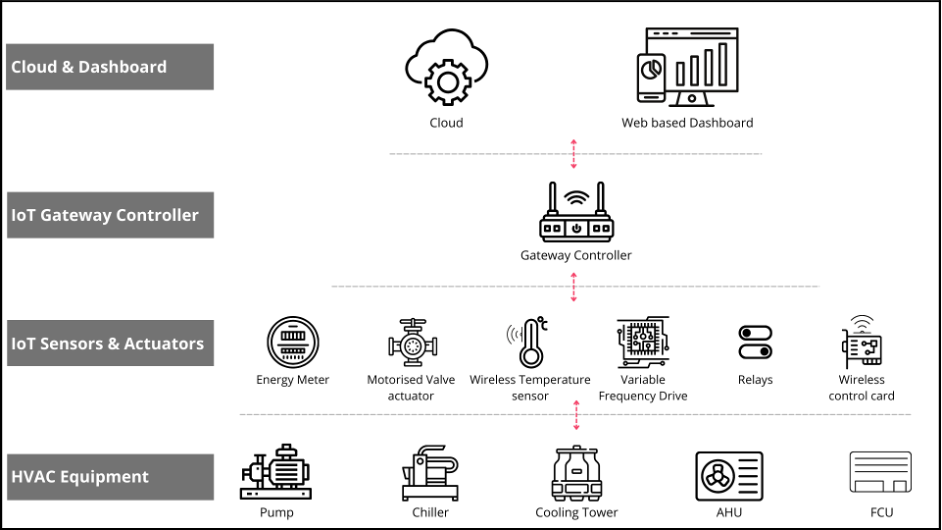

Several IoT devices such as sensors & actuators are deployed across the HVAC system. These are physical devices that can collect data and/or that can even perform actuation as per instructions. For instance, sensors like temperature sensors, humidity sensors, and CO2 sensors collect and wirelessly send the ambient environment data to the cloud-based system. On the other hand, an actuator can control the water valve or speed of the fan to maintain right temperatures as per the instructions from the cloud-based system.

Data collected from such IoT Sensors is processed over the cloud and then presented on a web-based dashboard for monitoring and control. The AI/ML-based analytics presents the data in the form of actionable insights such as alerts in case of abnormal behaviour of equipment or deviation from set ambient environment compliance. It’s also capable of taking corrective actions on its own if programmed to do so.

IoT intervenes and optimizes both the low side and the high side of an HVAC system. IoT intervention at the low side of the HVAC system allows for the modulation of variable frequency drives (VFD) & chilled water valves, and scheduling & duty cycling of the AHUs based on wireless IoT sensors. Furthermore, on the high side, it enables modulation of the chiller and the secondary pump based on leaving water temperature (LWT) and pressure sensors, respectively.

How IoT transforms a traditional HVAC system?

1. Smart HVAC Control & Automation

Smart HVAC controls assist in optimizing the conditioned air supplied throughout the building. Smart controls optimize airflow by using data such as temperature, humidity, CO2 levels, occupancy levels, duct static pressure, and so on, and modulate airflow in one area without under or over ventilating another.

Smart HVAC systems can also combine sensor data with inputs from external data sources, such as current and forecasted weather conditions, to control HVAC inside the building more effectively. The HVAC system can now be programmed to optimize occupant comfort while reducing energy consumption.

2. Smart HVAC Maintenance

HVAC systems are subjected to leaks, blockages, deterioration, and normal wear & tear on a regular basis, resulting in system degradation over time. HVAC systems powered by IoT use smart sensors to collect real-time asset health data such as temperature, pressure, vibration, rotation speeds, current, and so on. It then uses cloud-based AI/ML data analytics to detect irregularities in operations and potential flaws in equipment and processes in order to correct them before they fail.

This type of automated fault detection and diagnostics functionality results in a system that can continuously inspect HVAC components as they run. Such a proactive approach is far superior since it prevents problems rather than conducting maintenance at a set time or responding reactively when an issue arises.

3. Remote Asset (HVAC) Management

IoT technology provides centralized visibility & accessibility across all assets of multiple properties on a single platform that can be accessed remotely via a smartphone or a laptop. Individual HVAC system components can also be controlled remotely. Vents can be left open to promote ventilation in a specific area of the building, and temperature control for meeting rooms can be turned on and off throughout the day.

Dynamic and automated asset monitoring systems provide real-time data and visibility into a variety of parameters, including HVAC running status, health status, voltage status, and so on. Property managers can not only remotely monitor and manage the HVAC system, but it also allows maintenance staff to respond quickly to critical situations and do a post-mortem when problems arise, avoiding repeat of similar problems in the future.

4. Smart Multi-Zone Management

Smart HVAC systems powered by IoT provide dynamic control over each part of the building by regulating individual components such as ducts, vents, etc. With such a level of control, facility managers can utilize smart HVAC systems to set up several zones around the building with distinct schedules or unique humidity and temperature settings. This enables fine-grained control over various parts of the building, right down to individual rooms.

5. Modular Design Structure

One of the primary advantages of IoT architecture over a traditional architecture is its modular design approach. It’s a design principle that divides a system into smaller parts or modules that can be created, modified, replaced, or exchanged independently with other modules or systems. As a result, the entire system becomes easier to upgrade, maintain, and scale since only a portion of the system can be changed rather than the entire system.

6. Cloud based commissioning

All HVAC systems and components must be designed, installed, tested, operated, and maintained according to operational requirements. This process is known as commissioning. Remote commissioning is now possible, thanks to IoT technology. Cloud-based commissioning allows all software aspects of testing, deployment, and maintenance to happen over the cloud. The engineering team can be more productive because they can concentrate on problem-solving without being distracted by on-site circumstances. Furthermore, having all the right people in the same place makes processes more flexible, effective, and ensures optimal collaboration.

Benefits of IoT powered HVAC system

1. Predictive Maintenance

AI/ML-enabled data analytics in an IoT-powered HVAC system is more than just monitoring certain metrics, it’s also actionable. A common application of such smart analytics is FDD, or fault detection and diagnosis. As a result of such proactive maintenance, assets are always performing at their best and also at the most energy-efficient levels, resulting in overall energy savings. This is a big paradigm shift from routine (and periodic) maintenance or reactive response that is otherwise adopted in such environments.

2. Energy Savings

IoT can also automate HVAC operations, resulting in direct energy savings. Sensors in an IoT-powered HVAC system collect data from a variety of sources, such as ambient temperature, humidity, air quality, chiller return & leaving water temperature, and so on. It also employs a gateway controller to deliver data to the cloud. This data is then processed and returned as instructions to devices such as VFDs, Valve cards, and Relays retrofitted at various points in an existing HVAC system. These devices then use these commands to modulate various HVAC system components such as the chilled water valve, secondary pump, condenser pump, and so on. All this happens in a matter of seconds, without any human intervention.

3. Occupant comfort compliance

Indoor environmental aspects like air quality, temperature, humidity, lighting, etc., play a crucial role in occupant comfort & well-being. An IoT-based HVAC system can create the right ambient environment on its own. It can collect data via sensors, analyze it via AI-ML based cloud computing, and control the corresponding equipment via actuators & relays to maintain optimal environment.

In case there’s any deviation in the set environmental parameters, the appropriate personnel are notified so that the situation can be investigated and resolved as soon as possible without disrupting the occupant experience. IoT also enables predictive maintenance, reducing the likelihood of the HVAC system failing entirely in the first place. It’s a very effective technique as it provides the occupants with a seamless experience.

4. Centralized Visibility

Visibility is one of the key values delivered by an IoT system. The entire portfolio of properties can be viewed at once, similar to an eagle-eye view, that can be further drilled down to provide detailed information about each property, specific section of a property, and specific asset or equipment. Furthermore, with role-based access controls, multi-level visibility can be configured for a customized view for different stakeholders such as senior management, facility management, maintenance team, and so on.

5. Electrical safety compliance

When there’s a deviation between the current flowing in each phase of a three-phase supply, it leads to a current imbalance. A current imbalance generates excess heat, which can melt the insulation, resulting in stator winding faults and, as a result, causing spiral effect on the current imbalance. Unbalance also causes the electric motor to produce uneven torque, reducing its efficiency and increasing vibration. This eventually causes damage to the motor and the driven equipment. Therefore, it’s critical to monitor current and voltage balancing statistics because failing to do so can have serious consequences. Smart IoT energy meters constantly monitor these statistics and send alerts if any anomalies are detected. The appropriate team can then take corrective actions to avoid any serious consequences such as equipment or component failure.

6. Better return on (HVAC) investment

As mentioned, IoT powered HVAC system runs much more efficiently because of smart monitoring & control. Furthermore, because of predictive maintenance, HVAC components are kept in better condition, resulting in a longer total lifetime value provided by the HVAC system. Hence, a better return on the HVAC investment.

Why IoT?

Change scares people. Uncertainty about the impact of change is a major cause of resistance to change. Decisions are always influenced by the fear of the unknown. New technology, procedures, and systems can all cause uncertainty and, as a result, resistance to change. To avoid such uncertainties, let’s understand why IoT is going to be the future.

1. Hardware Light & Software intelligent

IoT technology is light on the hardware side i.e., requires minimal pieces of hardware and it’s software intelligent making this technology much more cost-effective, easy to deploy and scalable at the same time. These days many of the equipment such as pumps and valves are coming with their communication enabled versions. IoT enabled system will leverage direct connectivity with such equipment rather than putting an additional system on top thus resulting in a hardware light model.

2. Wireless Technology

Wiring makes systems difficult to deploy, use and scale. On the other hand, IoT is based on wireless technology powered by wireless mesh, such as Google’s OpenThread, LoRa, Zigbee, etc., that eliminates the need for wiring. Different zones within the building can independently communicate with the cloud and the identity of the building can be a soft notion in the cloud. This is different from complete wiring across all sensing and control sub-systems as is traditionally done in a building automation system.

3. OEM & Device Agnostic

IoT based HVAC solutions are OEM agnostic, i.e., such systems are compatible with any infrastructure that may consist of assets and equipment from several brands or even different technological eras.

4. Distributed Architectures

In a traditional HVAC system, DDCs are networked together and link up to a BMS room. While an IoT based HVAC system employs a distributed architectural approach wherein the gateway controller is independently connected with the internet and communicates directly with cloud servers. Hence the visibility and controls are not confined to the BMS room, rather they can be accessed via any smartphone or laptop.

5. Analytics Powered

IoT-based systems provide actionable insights via AI/ML-based cloud analytics. One of the smartest use cases of IoT powered data analytics in the asset management space is predictive maintenance powered by fault detection and diagnosis.

6. Shorter ROI Periods

By leveraging all of the aforementioned features, IoT-based asset and energy management solutions for various properties provide significantly shorter ROI periods (12-18 months) than traditional energy saving approaches.

IoT technology is causing a revolution in the HVAC industry. Sensors, gateways, wireless communication protocols, web-based dashboards, smart thermostats, intelligent vents, and other devices powered by the Internet of Things enable much smarter and energy-efficient HVAC systems. These systems can automatically adjust to changing environmental conditions and give building managers far more control over how their building is heated, ventilated, and cooled.

Keep up with the latest IoT-based building automation, and follow us on LinkedIn!